INTRODUCTION:

- Lighting, temperature, and humidity conditions must be optimal for plant growth.

- Choosing between a new construction or a repurposed building is a very important step.

- A new facility is more expensive, but you can save on HVAC with a high-efficiency building envelope.

- A professional MEP design is critical in a cannabis cultivation facility. Lighting, temperature, and humidity conditions must be optimal for plant growth.

- Choosing between a new construction or a repurposed building is a very important step. A new facility is more expensive, but you can save on HVAC with a high-efficiency building envelope.

3 THINGS TO CONSIDER BEFORE BUILDING A CANNABIS CULTIVATION FACILITY

As more states legalize recreational marijuana, opportunities to design and construct cannabis dispensaries and cultivation facilities are shaking up the commercial real estate market.

The strategy seems simple from an outside perspective — build a facility, bring in the product, and start making money. However, to ensure the facility is operating at its full potential, there are some serious considerations to keep in mind when developing these exciting spaces.

1 . BUILDING ENVELOPE EVALUATION

2. INSIDE THE BUILDING

3. UNDERSTANDING YOUR LOCAL JURISDICTION

BUILDING ENVELOPE ELEVATION:

It might seem obvious, but it’s worth mentioning that making sure your building meets the right qualifications for a successful cultivation facility is the most important part of the process, and that starts with the building envelope. The first major decision may be whether to build a brand-new building or repurpose an existing space. Reusing a building may save money at first, but costs may later be incurred while shoring up the interior’s insulation. Proper temperature and humidity control is crucial to quality cannabis production and ensuring your space’s effectiveness in the beginning will pay dividends in the long run. It’s beneficial to have an architectural and structural engineer survey the thermal and structural integrity of the building. Does the existing building insulation provide adequate moisture and temperature barrier for the building’s intended use? Can the existing structure support additional mechanical equipment and piping? This kind of information will help answer later questions when planning the facility’s layout, like determining whether mechanical equipment will be atop the roof or inside the building.

INSIDE THE BUILDING:

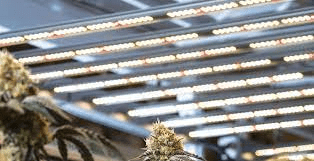

The most eye-catching aspect of a cultivation facility may be the racks-upon-racks of cannabis growing up to the ceiling, but these plants need a considerable number of systems to thrive. At the top of that list is humidity and temperature control. There are multiple stages of a plant’s life cycle, and each stage requires different conditions. Selecting the right HVAC system with adjustable humidity and temperature control for each stage is the most important operation. Another important system is the grow lighting system – which provides a consistent energy source plants need to grow healthy and strong. From HPS (high-pressure sodium) to LED (light emitting diode), there are many types of grow lights to choose from, allowing you to control the amount of light plants receive. There are many other systems to consider, such as carbon dioxide enrichment, fire protection, irrigation, and more. Consult with your mechanical, electrical, and plumbing (MEP) engineer to ensure necessary systems are designed for optimal plant growth.

UNDERSTANDING YOUR LOCAL JURISDICTION:

In this new and rapidly evolving industry, building codes and municipal rules are constantly changing, and since every state and county is different, it’s crucial to sit down with your team and local officials to understand the letter of the law. Procedures for inspecting installed assemblies, system coordination across multiple trades, and permit approvals may involve more red tape than you expect.

The cannabis industry is booming and it’s showing no signs of slowing down, so everyone is eager to choose their site location and get their spaces built. However, choosing a trusted contractor is just as important. Building according to codes and avoiding costly mistakes and delays is critical to quickly getting up and running.

Brunswick Engineering, a company registered in the states of NJ, NY & PA, offers Mechanical, Electrical, Plumbing & Fire Protection Engineering design services to both the public and private sectors. With a team of Registered Professional Engineers, LEED Accredited Professionals, Design Engineers, and CAD Draftsmen/Technicians, Brunswick Engineering is committed to delivering high-quality MEP services in line with sustainable building practices.